3 Simple Techniques For Laser Scanning Solutions, Llc.

Table of Contents8 Simple Techniques For Laser Scanning Solutions, Llc.The Only Guide for Laser Scanning Solutions, Llc.The Best Strategy To Use For Laser Scanning Solutions, Llc.How Laser Scanning Solutions, Llc. can Save You Time, Stress, and Money.

In order to position a laser beam of light in 2 dimensions, it is feasible either to rotate one mirror along two axes - utilized mostly for slow-moving scanning systems - or to reflect the laser beam of light onto two carefully spaced mirrors that are installed on orthogonal axes (https://0rz.tw/j67cj). Each of both flat or polygon (polygonal) mirrors is then driven by a galvanometer or by an electrical motor respectively

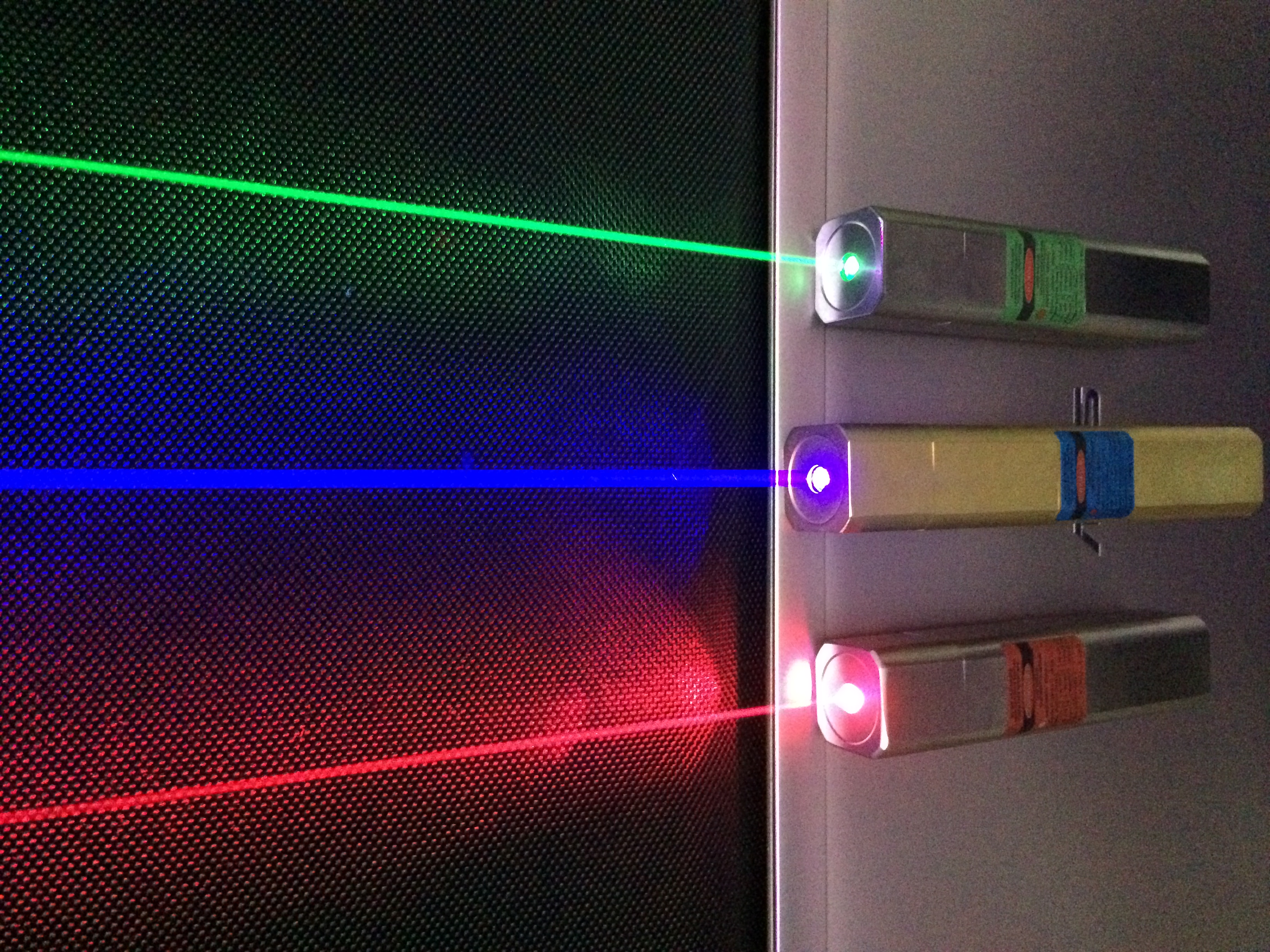

Numerous laser scanners even more enable changing the laser intensity. In laser projectors for laser Television or laser display screens, the three fundamental shades - red, blue, and environment-friendly - are combined in a single light beam and after that mirrored with each other with 2 mirrors.

Modern lasers can reduce steel blocks with a density of 10 cm and more or ablate a layer of the cornea that is just a couple of micrometers thick. The capacity of lasers to harden liquid polymers, along with laser scanners, is utilized in quick prototyping, the capacity to melt polymers and steels is, with laser scanners, to produce parts by laser sintering or laser melting.

7 Simple Techniques For Laser Scanning Solutions, Llc.

That card transforms the obtained vector data to movement information which is sent to the scanhead. This scanhead is composed of two mirrors that are able to disperse the laser beam of light in one level (X- and Y-coordinate). The third dimension is - if essential - recognized by a specific optic that has the ability to move the laser's prime focus in the depth-direction (Z-axis).

For these situations it is essential that the laser has as little a centerpiece as feasible (lidar scanning services near me). For improved laser scanning applications and/or high product throughput during manufacturing, scanning systems with even more than one scanhead are made use of. Right here the software needs to manage what is done exactly within such a multihead application: it is feasible that all offered heads have to note the exact same to end up handling faster or that the heads mark one single job in parallel where every scanhead performs a component of the job in instance of huge workplace

In these devices, a semiconductor laser light beam is usually checked with the aid of a resonant mirror scanner. The mirror is driven electromagnetically and is made of a metal-coated polymer. When a room transporter has to dock to the area terminal, it has to carefully steer to the proper position. In order to establish its loved one setting to the spaceport station, laser scanners built right into the front of the area transporter scan the shape of the spaceport station and afterwards establish, via a computer, the steering commands.

The usages just provided which are just a tiny sampling of laser scanning applications have widely varying technological needs. This includes specifications like scanning rate, the dimension of the location or quantity that must be covered, the laser power involved, the expense, size, dependability, and life time of the scanner, and a lot more.

The smart Trick of Laser Scanning Solutions, Llc. That Nobody is Discussing

Depending on the nature of the job, galvanometer scanners are frequently used in sets. Especially, in this instance they are installed with their check instructions at ideal angles per other. This enables the laser beam to get to any kind of factor in an aircraft. For many applications, specialized scan optics, like an F-theta lens, are made use of to concentrate the beam of light on the last surface area.

Going back to 1960, when Theodore Maiman designed the first laser, this type of light has evolved right into a tool made use of throughout markets. From medical treatment to manufacturing handling, the power of lasers is used across a myriad of industries and for several kinds of applications. When most think of lasers, the ubiquitous red light lasers commonly enter your mind.

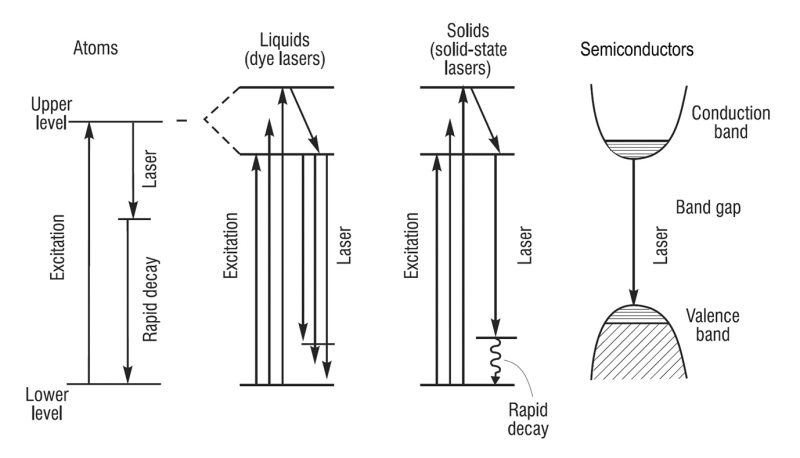

There are over eight kinds of lasers across 3 groups! Light wavelength circulation map Solid-state lasers are types of lasers that make use of a solid product as its gain medium.

All About Laser Scanning Solutions, Llc.

When a laser diode shines light on the doped product, the neodymium atoms are excited and emit light. This light is then amplified by the material and discharged as a laser beam of light.

These laser types make use of gas as the tool instead of a strong or fluid. The 4 kinds of gas lasers are CO2, He-Ne, excimer, and argon. Carbon dioxide gas lasers have the lengthiest wavelength compared to fiber, YAG, and YVO4.

Because of the long wavelength, there is even more heat transfer than other lasers. CO2 lasers are generally utilized for cutting products. He-Ne gas lasers have a wavelength of 630 nm and appear red to the human eye. He-Ne lasers are generally recognized for their usage as pointing gadgets in classrooms or throughout discussions.